The lubrication system has been developed in conjunction with the ALLPER-Plunger system to reduce the friction between the sleeve and the plunger; to thus ensure the smooth passage of the plunger through the sleeve. This is essential for consistent shot velocities and to extend the operating life of both the shot sleeve and the plunger tip. This is necessary for the long shot sleeve or when there is excessive wear under the pour spout.

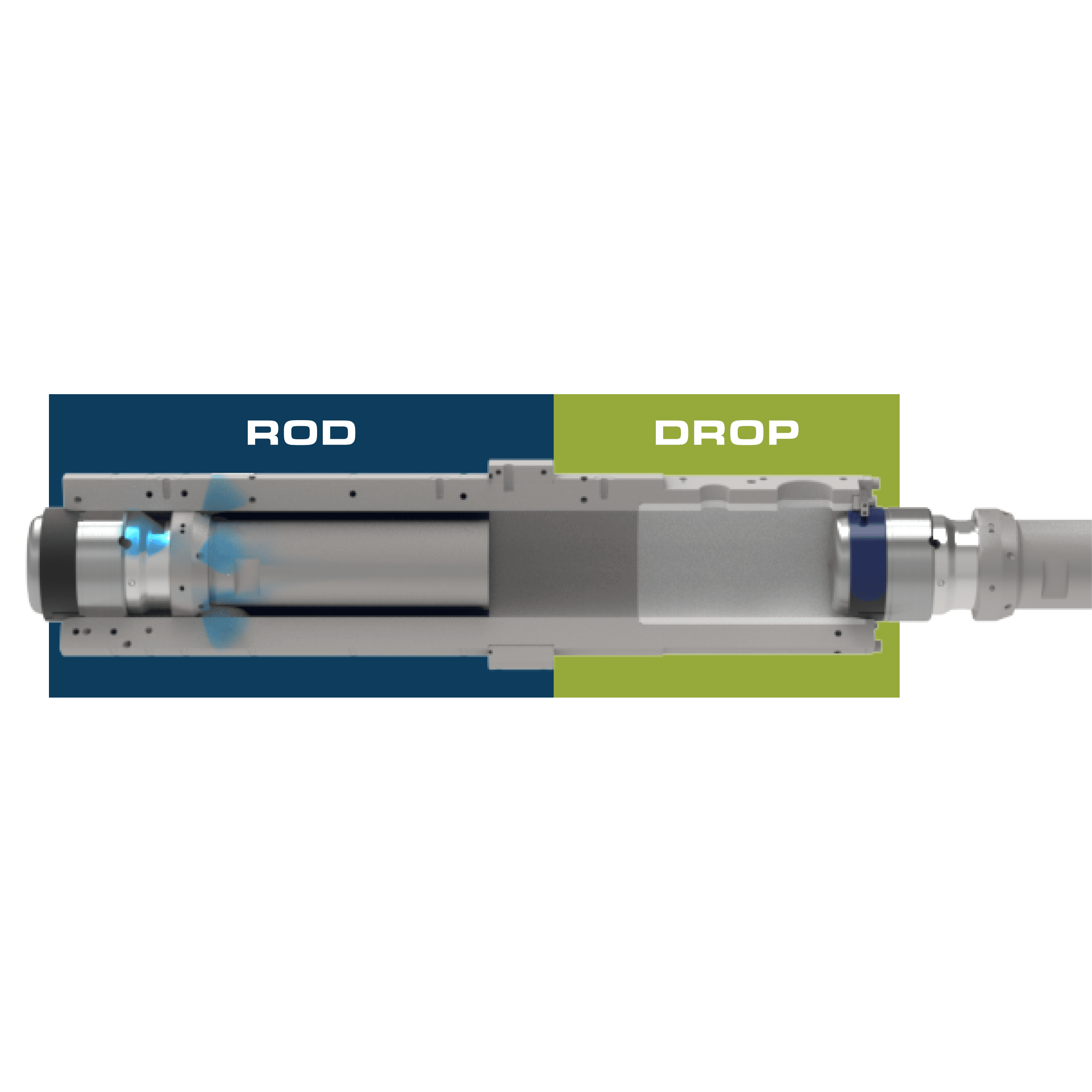

Rod-Lube and Lube-Drop

Castool’s shot sleeve/plunger lubrication system is designed to enhance safety and extend the lifespan of tooling components by applying a precise amount of lubricant only where necessary.

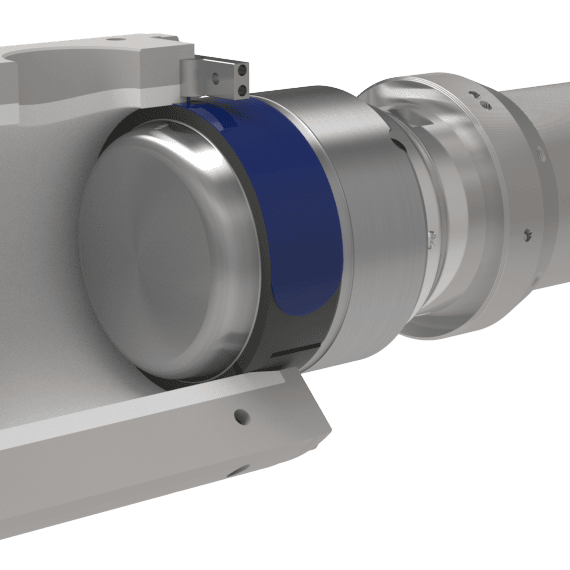

For small to medium shot sleeves, the system uses the bolt-on Allper Lube-Drop (ALD) or a machined slot and lubrication channel to deliver lubricant on top of the plunger ring.

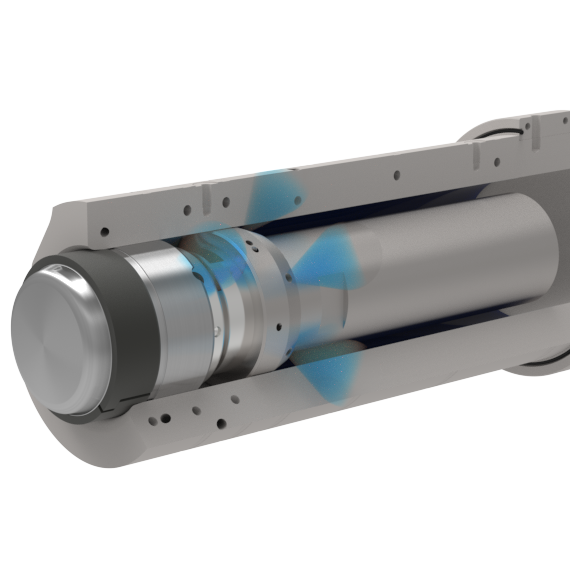

For longer shot sleeves, the Castool Rod Lube (CRL) system applies a small amount of lubricant on the die-end bore of the shot sleeve before the plunger returns.

This system can be used alone or in combination with the ALD.

The key takeaway is that lubricant should be applied sparingly to avoid unnecessary costs, prevent workplace pollution, and to prevent any non-metallic substances from contaminating the casting process.

A carefully measured amount of lubricant is applied between the ring, sleeve and impact zone right under the pour hole. This ensures complete coverage without costly overspray. A controlled dosage injection pump provides the precise amount of lubricant required for each process cycle. This controlled dosage prevents the danger of contaminating the casting with excessive lubricant.

All lubricants used in combination with our dispensing units

ALD (Allper Lube-Drop),

ACL (Aller Combi-Lube)

and CRL (Castool Rod Lube) bring the following advantages:

- minimum volume of lubricant used (the right amount at the right place)

- no lubricant loss

- clean environment DCM

- lifetime improvement of the shot sleeves and plunger tips

CLS - 200: Plunger Lubricant

Vegetable ester based lubricant that is biodegradable. It is blue in colour, remains as a solution and has a high flashpoint. It is also low smoke, and very well priced.

Type: CLS-200 Vegetable ester based

Part No: CLS-200 Lubricant

Packaging: 19 L pail, 208 L drum or 1,250 L tote

Usage: Plunger tip lubricant formulated for lubrication of all types of plunger tips: beryllium copper, bronze, steel and all diameters.

Purpose

- Reduce friction between the sleeve and the plunger

- Provide consistent shot velocities

- Extend the operation life of both shot sleeve and plunger trip

- Eliminate the contaminates getting into the casting

Function

- A carefully measured amount of lubricant is vaporized to form a fine mist.

- The lubricant spray and air nozzle assembly is securely mounted just behind the plunger assembly.

- The nozzle technology effectively atomizes the lubricant to reduce overall consumption.

- Nozzles can be quickly interchanged to provide different spray patterns.

- Spray pressure and duration are both adjustable.

- Reduce cost per shot

- Increase plunger life

- Increase shot sleeve life

- Reduce contaminates

- Reduce scrap rate

- Reduce downtime