The Plunger tip is a critical element of aluminum die casting process. Its successful operation depends on a number of factors. The most important factor is its efficient interaction with a round, straight, thermally and therefore dimensionally stable shot sleeve.

Castool’s plunger tips were developed a number of years ago by Allper of Switzerland. The plunger materials have been developed jointly between Allper and SCHMELZMETALL over the last 30 years particularly for die-casting. All the copper alloys are refined from virgin materials, heated and casted in high vacuum to avoid oxides, forged and thermally precipitated. The alloy combines high fatigue, high hardness, high resistance to heat and high thermal conductivity

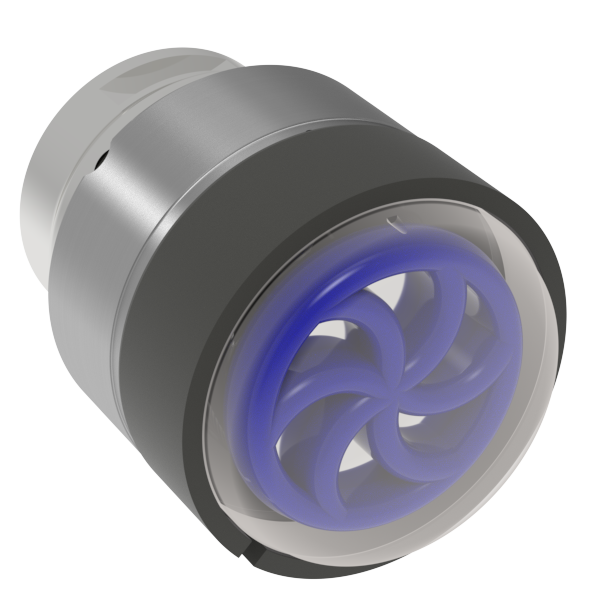

THE ABP PLUNGER

The Allper Bush Plunger – ABP was developed for small to medium-sized machines, from 40 mm up to 120 mm in diameter.

ABP-R 50 TO 120 MM DIA – This ABP-R incorporates a forged Con-Duct steel body, a forged BeCu bushing, a nitride hot work tool split ring, and a steel coupling.

ABP-A (Solid) – In some cases, because of the die or shot sleeve configuration, it is difficult to use the split ring. In these cases, it is possible to use the ABP without a split ring.

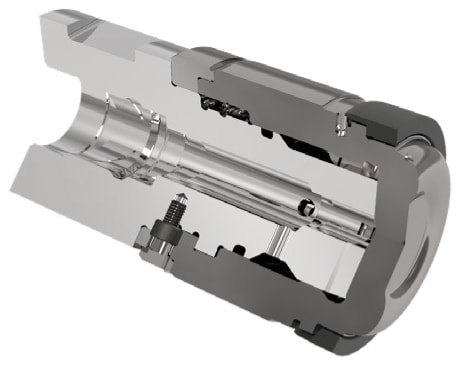

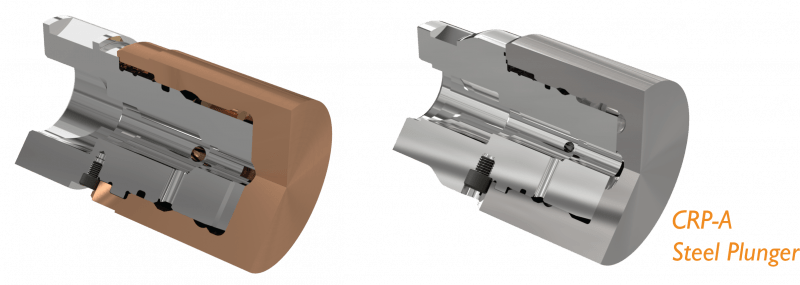

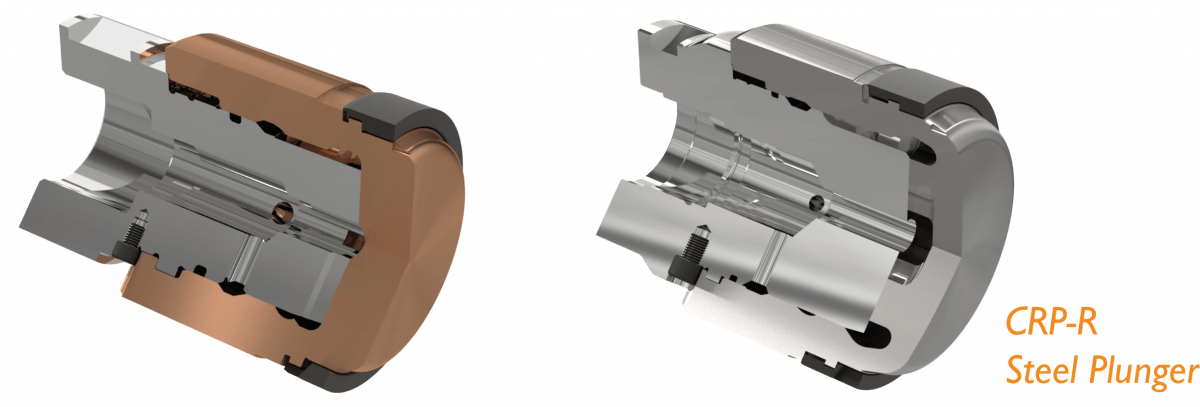

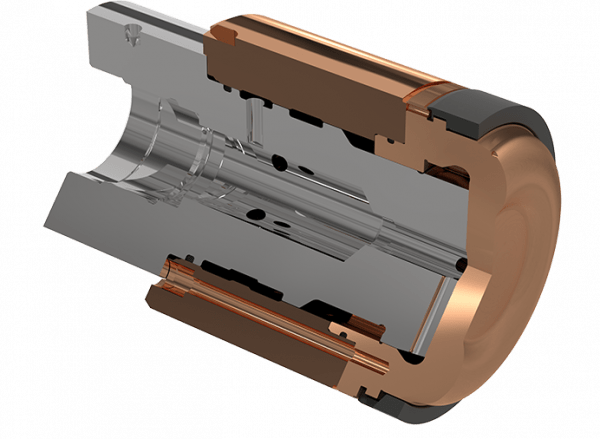

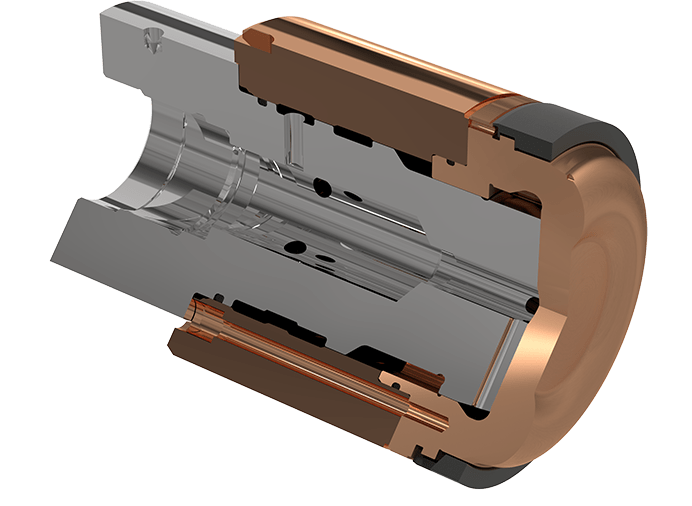

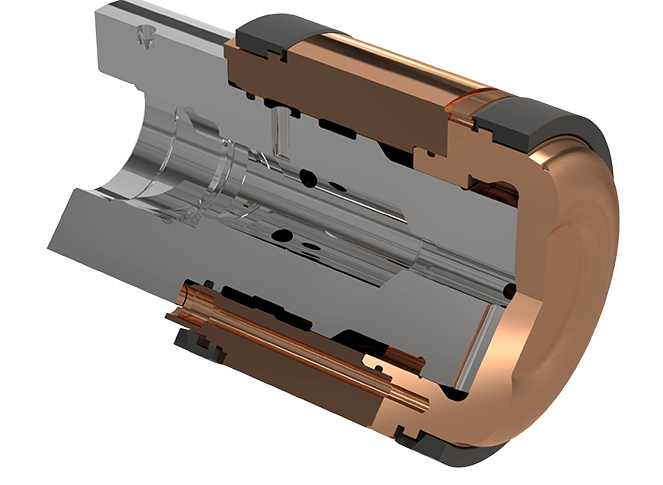

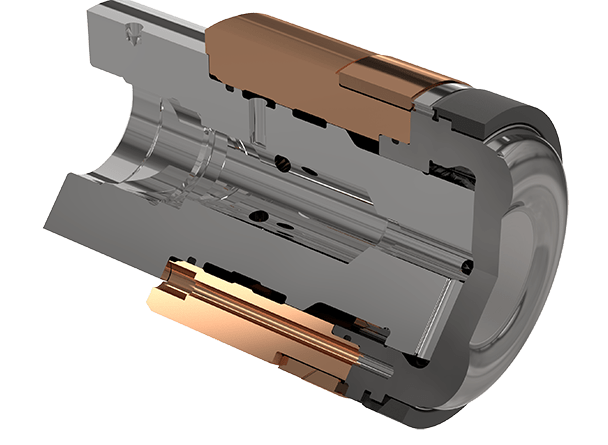

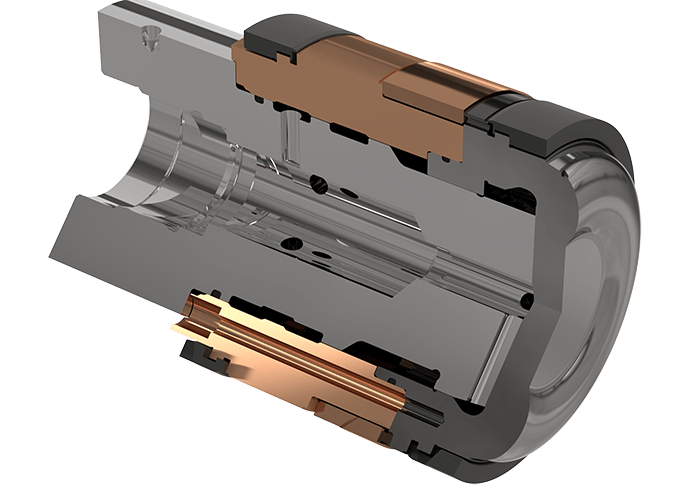

The Allper Ring Plunger (ARP) / The Castool Ring Plunger (CRP)

The ARP is recommended for medium machine, from 40 mm up to 220 mm diameter.

ABP-R – This incorporates a forged Con-Duct steel body, a forged BeCu bushing, a nitride hot work tool split ring and a steel coupling.

ARP-A – A solid forged beryllium copper or Con-Duct tip is fastened to a stainless steel holder with a quick release bayonet coupling.

ARP-R – An expanding steel (H13) or copper wear ring (A52 or A25) wear ring is attached to the beryllium copper or Con-Duct ARP plunger tip.

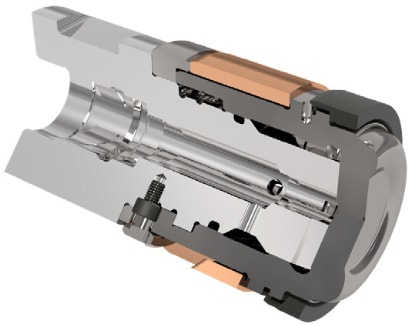

AMP-A – In some cases, because of the die or shot sleeve configuration, it is difficult to use the split ring. In these cases, a forged ultra high strength Con-Duct steel or beryllium copper head is attached to the AMP stainless steel holder and copper body and copper body.

AMP-R – A nitride H-13 (1.2344) steel ring rests freely in a groove machined near the front of the AMP plunger tip. It is split, and expands against the inside wall of the shot sleeve to maintain a better seal. The cost of consumables is reduced.

AMP-RR – Similar to the AMP-R, but has two expanding wear rings instead of one, specifically for large, convoluted close-tolerance castings.

AMP-RV – The RVR incorporates a forged beryllium copper bushing around the copper body. A more positive seal is achieved.

AMP-RVR – The RVR incorporates a forged beryllium copper bushing around the copper body, between the 2 rings. A more positive seal is achieved.

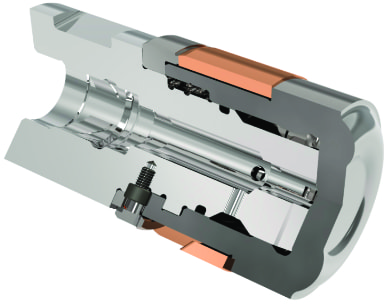

Purpose

- Prevent alloy from penetrating between the shot sleeve and plunger, prolonging tooling life.

- Move smoothly and consistently, with a minimum of lubrication, through the shot sleeve bore increasing casting properties.

- Maintain a secure seal with the shot sleeve wall necessary for an effective vacuum to be drawn reducing porosity.

- Cool the biscuit quickly to reduce cycle times.

Function

- The function of the plunger tip is the extension of the plunger rod, which pushes the molten alloy into the mould. There are a number of functions that must be satisfied by an effective plunger tip.

- To repeatedly transmit the force of the plunger rod, at high temperature, to the alloy.

- To maintain a seal with the shot sleeve wall during the shot, eliminating flash or blow-by and preventing air from being drawn into the alloy when using a vacuum.

- To remain thermally and therefore dimensionally stable throughout the shot allowing consistent and repeatable shot velocities.

- Since the tip is dimensionally stable, and the gap controllable, steel wear rings can be attached to the plunger tip body to provide a guarantee that the seal is maintained.

- Because the rings is flexible, it makes continuous contact with the inside of the shot sleeve. Flash, which is a major cause of wear, is essentially eliminated. Shot speeds are consistent.

- Since the expanding wear ring ensures a secure seal between the plunger and the shot sleeve, a better vacuum can be drawn.

- An additional advantage is that the face of these is considerably cooler than that of other plunger tips. This cools the biscuit much faster, and reduces the cycle time significantly

- Reduce cost per shot

- Increase plunger life

- Increase shot sleeve life

- Improve vacuum seal

- Reduce scrap rate

- Reduce downtime