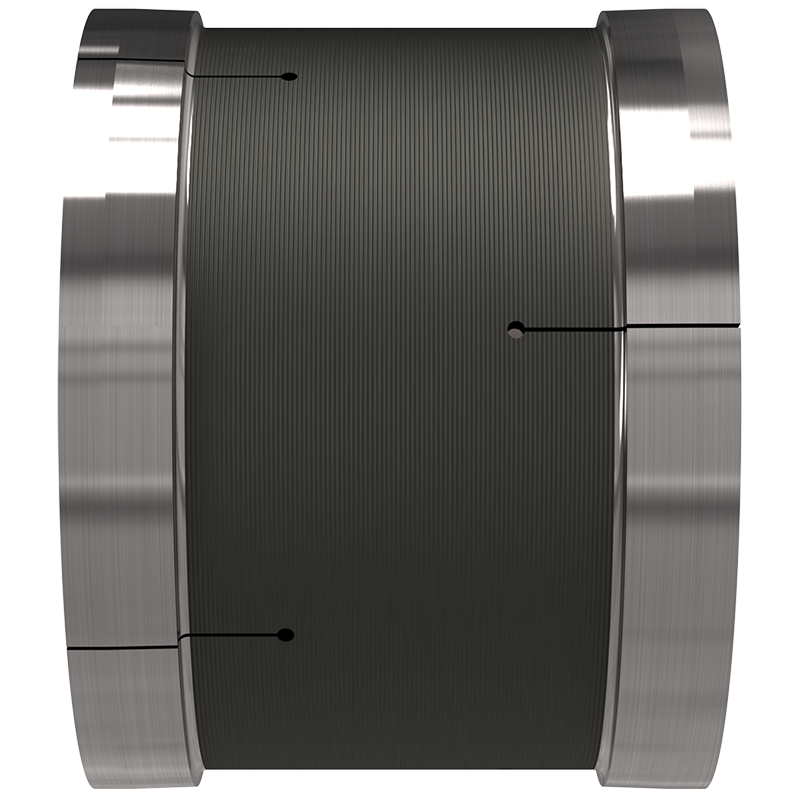

The Castool Clean-Out Block has been designed for maximum efficiency in cleaning the liner wall. The block is long enough to sit on the billet loader and travel through the liner smoothly. It is made to be used at room temperature to make handling safer and to achieve better dimensional control. The block is made hollow to reduce weight and wire cut at both ends to allow it to flex slighty and retain contact with liner wall.

Once the customer has supplied the minimum container liner diameter at room temperature and the operating temperature of the liner, Castool applies the thermal expansion factors for both the liner and the clean-out block to calulate the best diameter for the cold clean-out.

The Castool clean-out block is precisely sized to meet the requirements of each individual container, and to remove the maximum amount of skull without abrading the liner wall.

The amount of expansion of the dummy block is carefully calculated and controlled in order to leave a thin film of alloy, or “skull”, on the liner of the container, as the dummy block shears the metal during its forward stroke. The container then has a residual built-up oxide layer prior to the next billet being loaded. After billet upset, the oxide layer of the new billet mixes with the previous layer left in the container. When the alloy is changed, there is then a possibility of contamination. This can result in defects in surface finish, or in structural properties.

The dummy block should never remove the skull completely, because it separates the outer surface of the dummy block from the liner of the container. If there is no alloy left, it usually indicates that the dummy block is not contracting on the return stroke. Scrap from the skin of the billet being extruded, as well as blisters and other defects in the product, will result.

Through the ongoing development of metal treatment and casting technologies, the quality of alumimum alloy billets is constantly improving. The outer skin of the billet, however, is inevitably oxidized, and often also marred by surface impurities and minor inclusions.

Aluminum’s property of sticking to steel causes the oxide skin of the billet to remain fused to the interior surface of the container liner during extrusion. It is important to prevent this layer of tainted alloy from sliding forward toward the die.

During the extrusion stroke, as the billet is pressed through the container, the flow into die is from the center of the billet.

Oxides and other impurities from the skin then collect in front of the dummy block. Extrusion is stopped before this contaminated alloy is carried through the die into the product. It then forms the butt that adheres to the back of the die stack, and is discarded.

- One alloy family to another (for example 6XXX to 5XXX or 7XXX to 2XXX)

- Within an alloy family : as required by product quality demands

- Within an alloy family (6XXX alloys only) : when changing from a hard 6XXX alloy to a soft alloy (from 6061 alloy to 6063)

When encountering persistent blister along the length of extrusion:

- Use Cold Clean-out Block to remove skin build up in container

- This is just a temporary fix. The real cause of the problem needs to be addressed (for example, container liner is worn or bellied; there is stem to container misalignment; or dummy block is in need of replacement)

Purpose

- Clean-out block is pushed through a heated container by the dummy block.

- It should remove all the aluminum left on the inner bore of the liner after repeated extrusion cycles

Function

- A dummy block that is working properly will leave approximately. 005” (.25 mm) of aluminum on the inside of the liner. The clean-out block should remove this, having zero clearance with the liner in the heated condition.

- When ordering a clean-out block, it is important to accurately measue the current bore of the entire length of the container. Normally a container may be used for an extended period, but especially if hard alloys are being extruded, over time the actual diameter will increase.

- Temperature control of both container and dummy block is critical for efficient extrusion. Taper heating of the billet, however, makes cooling of the dummy block no longer necessary.

- Also, neither clean-out blocks nor dummy blocks can operate effectively if the container has become out of round, bellied, or gouged. Such containers should either be relined, or replaced.

- It is relatively safe to handle, because it is hollow/light and at room temperature

- Because it is quite long, it can sit on the billet loader and also enter the liner bore without skewing

- When properly sized, most of the alloy left in the container bore is removed.