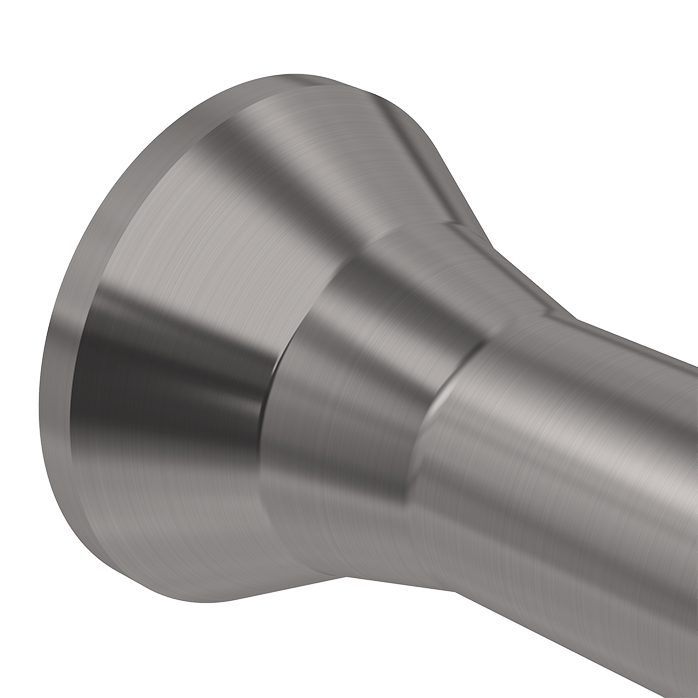

The high pressure from the dummy block transfers to the stem, making it essential that the load be uniformly applied. In addition, since the stem operates repeatedly and consistently under very high compressive loads, it must remain completely in alignment through its stroke length.

The material most commonly used for extrusion stems is Premium Forged AISI H-13 (1.2344) hot working tool steel and forged tool steel. The stem is heated to austenizing temperature, quenched and tempered to obtain hardness in the range of 415-460 Brinell (Rockwell C44-48). Its strength depends on its continued hardness at operating temperatures, and also on the absence of internal stress.

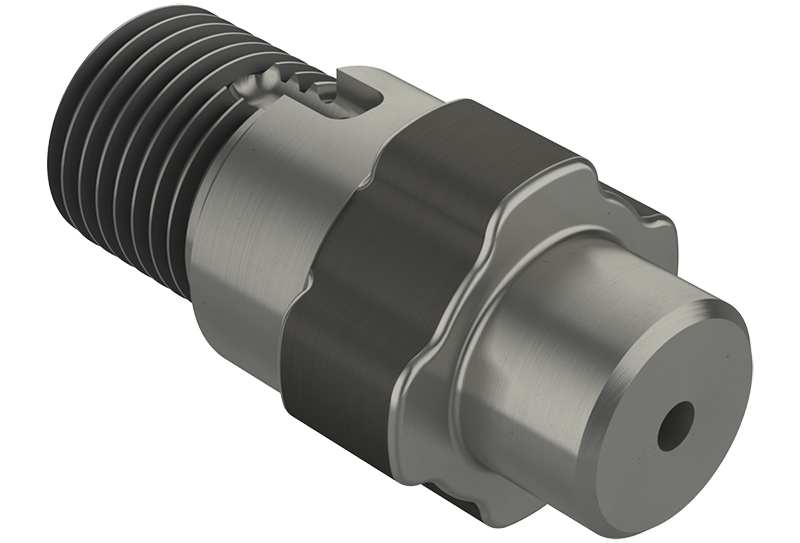

Maintenance Existing stems can be adapted to the Castool bayonet system by attaching a spacer. The stem is cut and thread machined in the bore to accept the spacer stud. It is important that the stem and spacer faces match exactly, and that there are no gaps. A dowel pin must be installed on the diameter of the stem/spacer to prevent rotation. If a gap develops between the stem and the spacer, the stud will then bear the full pressure of the ram, thread foul and be extremely difficult or impossible to remove.

Stems should be Stress Relieved on a regular basis, and in accordance with the size of the press and the number of pushes. (See suggested frequency below) The stem should be positioned vertically in the oven, and heated at no more than 100 0 F (55 0 C) per hour to 1000 0 F (540 0 C), then held at this temperature for one hour per inch (25 mm) of stem diameter. Remove from furnace and allow the stem to cool in still air at room temperature

Existing stems can be adapted to the Castool bayonet system by attaching a spacer. The stem is cut and thread machined in the bore to accept the spacer stud. It is important that the stem and spacer faces match exactly, and that there are no gaps. A dowel pin must be installed on the diameter of the stem/spacer to prevent rotation. If a gap develops between the stem and the spacer, the stud will then bear the full pressure of the ram, thread foul and be extremely difficult or impossible to remove.

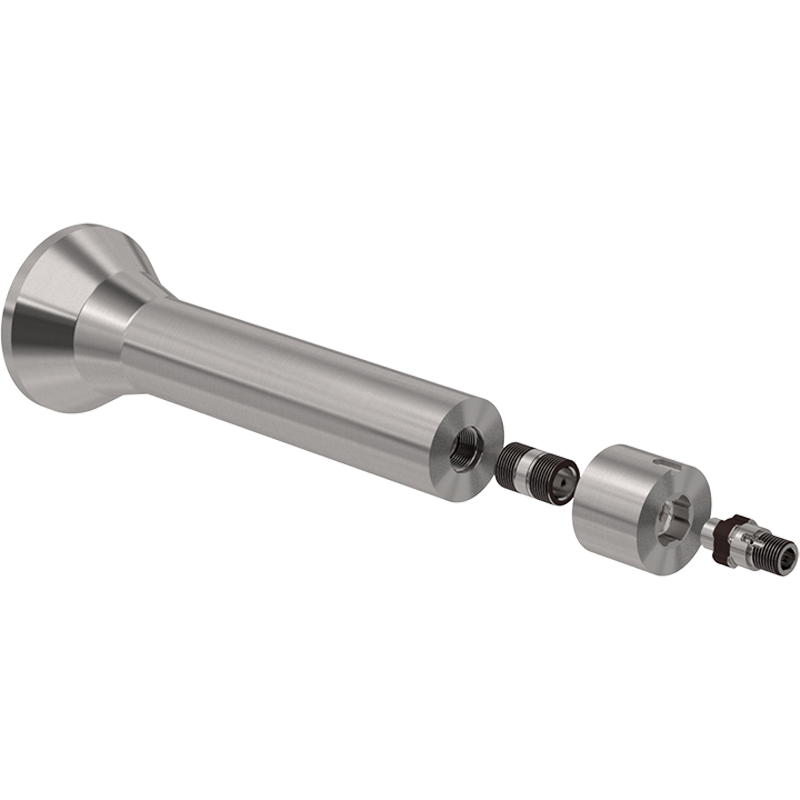

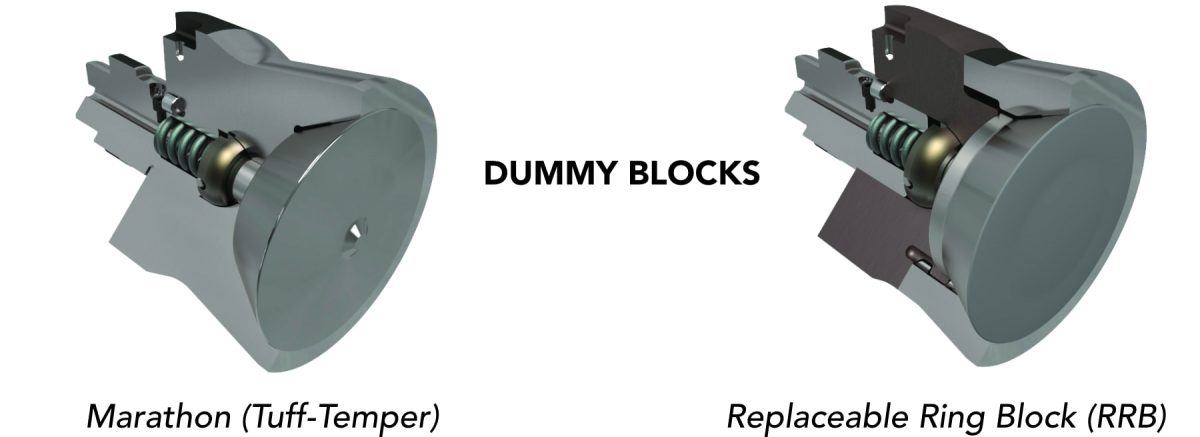

Castool uses a unique bayonet-type coupling which locks the dummy block quickly and securely to the stem. This makes it much easier and faster to replace a very hot block than with a conventional screw-type or rod coupling. A secondary stabilizing stud is used to prevent lateral movement for newer presses where alignment is not an issue. Care must be taken when designing and machining the bayonet coupling in the stem to avoid potential stress risers that can cause breakage.

Stems should be Stress Relieved on a regular basis, and in accordance with the size of the press and the number of pushes.

The stem should be positioned vertically in the oven, and heated at no more than 1000F (55 0C) per hour to 1000 0F (540 0C), then held at this temperature for one hour per inch (25 mm) of stem diameter. Remove from furnace and allow the stem to cool in still air at room temperature.

Purpose

- Transmits the force of the main cylinder to the billet

- Must operate under high loads without bending, cracking or upsetting

Function

- The stem must operate repeatedly and consistently under very high compressive loads. It is essential therefore that it remains in complete alignment throughout the length of its stroke. The alignment should be checked weekly.

- Because of the high pressures carried by the stem, it is essential that the load be uniformly applied. Uneven loading will eventually cause bending or breaking. This can result from a variety of reasons such as improper installation, distorted pressure plate, misaligned press, jammed butts (causing the container to shift), or improperly cut billets.

- As noted above, care must be taken to avoid these situations as the stem can break catastrophically.

- Longevity and safety

- Only premium grade forged H-13 (1.2344) and experienced heat treatment is used.

- Designs are modelled using FEA and machined to reduce stress risers that may causes cracks risers that may causes cracks.

- Stabilizing stud allows benefits of bayonet coupling with minimal lateral movement.